Polycarbonate plastics were first discovered by Dr. Hermann Schnell and Dr. Daniel Fox) in 1953 at the General Electric Company. They were trying to develop a new type of material that could be used for electric insulators, but instead, stumbled upon a transparent and highly durable plastic. This new material was named "Lexan" by GE, and it quickly gained popularity due to its superior performance compared to other plastics at the time.

Polycarbonate plastics were first discovered by Dr. Hermann Schnell and Dr. Daniel Fox) in 1953 at the General Electric Company. They were trying to develop a new type of material that could be used for electric insulators, but instead, stumbled upon a transparent and highly durable plastic. This new material was named "Lexan" by GE, and it quickly gained popularity due to its superior performance compared to other plastics at the time.

Polycarbonate is a type of thermoplastic polymer that is commonly used in a variety of applications due to its durability, transparency, and heat resistance. The chemical composition of polycarbonate is characterized by a repeating unit known as a carbonate group, which consists of three atoms: one carbon atom (C), one oxygen atom (O), and one additional oxygen atom that is double-bonded to the carbon atom (O=C-O). The chemical formula for polycarbonate can be represented as follows:

(-O-C(=O)-C6H4-C(=O)-O-)n

where "n" represents the number of repeating units in the polymer chain, and C6H4 refers to a phenylene group, which is a benzene ring (C6H5) with one hydrogen atom replaced by a carbon atom. The phenylene groups alternate with the carbonate groups in the polymer chain, resulting in a linear and highly branched structure. This molecular arrangement contributes to the unique properties of polycarbonate, such as its high impact strength, optical clarity, and resistance to UV radiation.

Polycarbonate has a relatively high glass transition temperature. The glass transition temperature is the temperature at which a polymer transitions from a glassy, rigid state to a rubbery, more flexible state, called Tg. Below the Tg, polycarbonate is in a glassy state and has a high modulus, meaning it is stiff and brittle. Above the Tg, polycarbonate transitions to a rubbery state and its modulus decreases, making it more flexible and capable of flowing or deforming under stress.

The Tg of polycarbonate typically ranges from about 145°C to 155°C. When polycarbonate is heated above its Tg, it becomes softer and more pliable, allowing it to flow and take on the shape of the mold or container it is placed in. This property makes polycarbonate suitable for a wide range of applications, including injection molding, thermoforming, and extrusion, where it can be melted, shaped, and cooled.

The Tg of polycarbonate also impacts its thermal stability. Polycarbonate has good thermal stability below its Tg, meaning it can withstand relatively high temperatures without significant degradation. However, above its Tg, polycarbonate can undergo molecular mobility and may be prone to degradation or reduced mechanical properties if exposed to prolonged elevated temperatures.

In the years that followed the discovery, polycarbonate plastics found widespread use in various industries. One of the early milestones was the development of bulletproof glass in the 1960s, which utilized the high impact resistance of polycarbonate to provide enhanced protection. Polycarbonate was also used to make eyeglass lenses, providing a lightweight and shatter-resistant alternative to glass lenses. Over the years, advancements in processing techniques and material formulations have led to further improvements in polycarbonate properties and expanded its applications in automotive parts, medical devices, and consumer goods, among others. The Lockheed Martin F-22 Raptor's canopy is constructed of specialty polycarbonate.

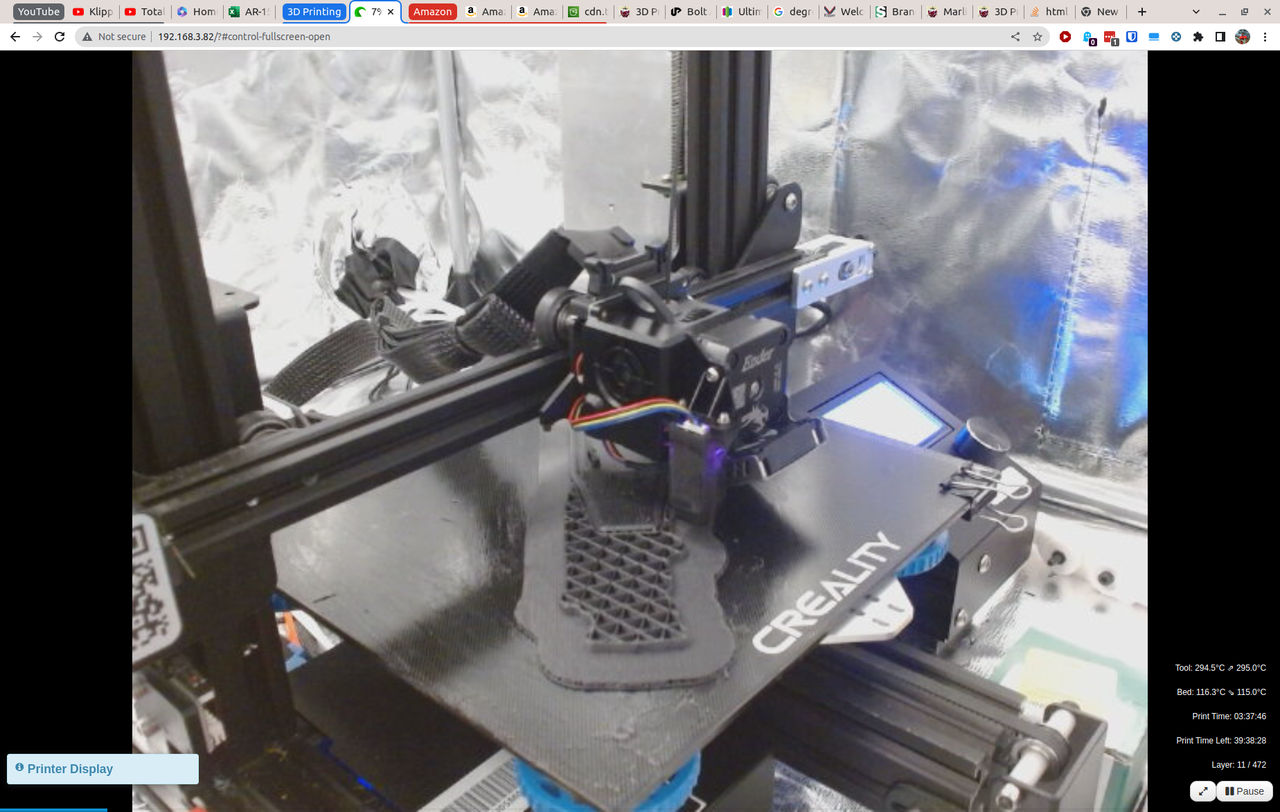

Enter, fused filament fabrication (FDM), or what most call, 3D printing. Using pure polycarbonate (whatever that actually means) as a 3D printing material can be extremely frustrating when using a desktop or kit 3D printer. You will need to be able to achieve temperatures that most retail printers are not capable of out of the box. You will need an all metal hotend that can handle temperatures at or above 300°C. Likewise, your build surface will need to be able to achieve temperatures exceeding 100°C.

If you are one of the few repeat readers of this site, you will know that I am a fan of Creality's Ender 3 Pro model of 3D printers. The Ender 3 Pro has been on the market for years, has a loyal following, and has a near endless array of aftermarket upgrades. Check out Scott Yu-Jan and his awesome Ender 3 Pro modifications. In previous posts (here, here and here), we were printing variants of nylon with fiber reinforced filaments, Like polycarbonate, nylon requires higher temperatures than normal PLA filaments. You can use the same aftermarket upgrades for our hotend, a Creality Sprite Pro. This has been a solid upgrade to my Ender 3 Pro printers; I would highly recommend it, even if you are only printing PLA. I have tried other direct drive Ender 3 Pro upgrades, and the Sprite Pro has shortest piece of internal bowden tube. The ease of loading filament is also a huge plus. There is a lower priced Creality Sprite that is not rated for high temperatures; you might be able to get by with this for printing nylon-based filaments, it would definitely work extremely well for printing with PLA filaments.

The other significant upgrade is the build surface. I upgraded to a Gulf Robotics' silicone encased all aluminum, three point build plate. This is an upgrade that might not be necessary, as the stock build plate as reach temperatures of 100°C, but, anecdotally, the heating is not as even as the Gulf Robotics' build plate. It heats up quicker, has more evenly distributed heat, and should be able to tolerate higher temperatures for longer periods of time compared to the stock build plate. As an addition to the upgraded build plate, I also decided to insulate the underside. I used Befenybay lightweight insulation. Silicone springs were also used. As an aside, I am planning on building and upgrading an Ender 3 Pro and tracking the build time as well as costs associated with making a high temperature, advanced materials printer. This will include setting Klipper firmware. Why Klipper instead of Marlin? You will have to come back to read why.

The other significant upgrade is the build surface. I upgraded to a Gulf Robotics' silicone encased all aluminum, three point build plate. This is an upgrade that might not be necessary, as the stock build plate as reach temperatures of 100°C, but, anecdotally, the heating is not as even as the Gulf Robotics' build plate. It heats up quicker, has more evenly distributed heat, and should be able to tolerate higher temperatures for longer periods of time compared to the stock build plate. As an addition to the upgraded build plate, I also decided to insulate the underside. I used Befenybay lightweight insulation. Silicone springs were also used. As an aside, I am planning on building and upgrading an Ender 3 Pro and tracking the build time as well as costs associated with making a high temperature, advanced materials printer. This will include setting Klipper firmware. Why Klipper instead of Marlin? You will have to come back to read why.

I will call this out in its own paragraph: you will need to update your Marlin firmware. This article will only get you so far. You will need to modify a few other settings.

#define HEATER_0_MAXTEMP 340

#define BED_MAXTEMP 170

#define HOTEND_OVERSHOOT 10

// #define EXTRUDER_RUNOUT_PREVENT

Download High Temperature Marlin Firmware (April 16, 2023)

The first two temperature changes just might be too extreme, but I picked subjectively high values because I was running into temperature overshoot faults. Initially setting the hotend temperature to 320°C with an overshoot value of 20°C, when your gcode temperature was set to 300°C and with the variability of heating element, this routinely resulted in those temperature faults. By, increasing the hotend temperature and narrowing the overshoot value, this seemed to allow for higher temperatures without risking a temperature fault.

The first two temperature changes just might be too extreme, but I picked subjectively high values because I was running into temperature overshoot faults. Initially setting the hotend temperature to 320°C with an overshoot value of 20°C, when your gcode temperature was set to 300°C and with the variability of heating element, this routinely resulted in those temperature faults. By, increasing the hotend temperature and narrowing the overshoot value, this seemed to allow for higher temperatures without risking a temperature fault.

The last option, disabling runout prevention was necessary because I ended up destroying a Sprite Pro. How? Somehow, the printing stopped, and the hotend carriage got parked in one place. Every 10 seconds or so, a small amount of filament was extruded. Let this run over night, and you end up with a blob of reinforced polycarbonate that encases the nozzle, silicone sock, part of the cooling fan nozzle, as well as part of the heat sink.

In attempting to dislodge the blob of hardened polycarbonate, the two screws that hold the heat block (where the nozzle screws in) to the heat sink snapped. The whole Sprite Pro unit might be salvageable, and I do have a Sprite that can be used for parts, but I will need to expose enough of the screws to use a needle nosed plier to turn them.

Filament

Let's get down to the brass tacks on using polycarbonate filament. 3DXTech has an easy to print carbon fiber reinforced polycarbonate (or here). All of the reinforced filaments are relatively expensive compared to non-reinforced PLA or ABS filaments. You can start with easy to print polycarbonate filaments to save a little bit of money before taking the jump into reinforced filaments. Using non-reinforced filaments would also allow for the use of a 0.4mm nozzle, which should result in finer details coming through better than with a 0.6mm nozzle.

You will need an enclosure, but it is not necessary to have a heated enclosure. I have found the Gulf Robotics' upgraded build plate heater does a great job of increasing the enclosure's ambient temperature without needing another heating source.

Another tip for successful printing is to use a raft instead of a brim or skirt. Using a raft results in as much build surface contact as possible. Polycarbonate does not stick very well to most surfaces - it will gladly stick to itself. I used an adhesive - a Nano Polymer Adhesive (or here). It is not cheap. But, putting a few layers of adhesive onto the glass build surface, along with a temperature of 115°C and a raft, I have had little issues with prints becoming dislodged. PEI build plate surfaces are also said to have great adhesion properties for polycarbonate filaments.

Good luck and leave a comment if you print, successfully or unsuccessfully, with reinforced polycarbonate filaments.