Introduction:

Pure nylon may not always provide the required strength for certain applications. This is where glass reinforced nylon, carbon fiber reinforced nylon, and kevlar reinforced nylon comes in; it offers improved strength and durability while retaining the advantages of nylon. As we have already covered carbon fiber and Kevlar reinforced nylon, we will explore the discovery of glass reinforced nylon, its technical properties, and its uses in 3D printing.

The discovery of glass fiber reinforced nylon is attributed to several researchers and engineers who were working on improving the mechanical properties of nylon in the 1960s. One of the most notable contributors was Dr. Herman Mark, a polymer scientist who worked at the Polytechnic Institute of New York University. In the early 1960s, Herman and his team discovered that the addition of glass fibers to nylon significantly improved its strength and stiffness. This led to the development of glass fiber reinforced nylon, which was initially used in the automotive industry for components such as engine covers and air intake manifolds. Since then, glass fiber reinforced nylon has found its way into many different applications, including the 3D printing realm.

Glass reinforced nylon is a composite material made of nylon and glass fibers (pretty obvious, isn't it?). The glass fibers are usually added in the form of short fibers or long continuous strands, which are mixed with the nylon during the manufacturing process. The addition of glass fibers to nylon improves its mechanical properties, making it stronger, stiffer, and more resistant to wear and tear. The amount of glass fibers added to nylon can vary, with higher percentages resulting in higher strength and stiffness but lower ductility. Also, because glass is generally colorless, nylon + glass fiber is available in various colors compared to nylon + carbon fiber's only color of black.

The mechanical properties of glass reinforced nylon make it an ideal material for 3D printing applications. Glass reinforced nylon has excellent strength and stiffness. It also has good chemical resistance, making it resistant to solvents and chemicals, and can withstand high temperatures, making it suitable for applications such as automotive components and electronic enclosures.

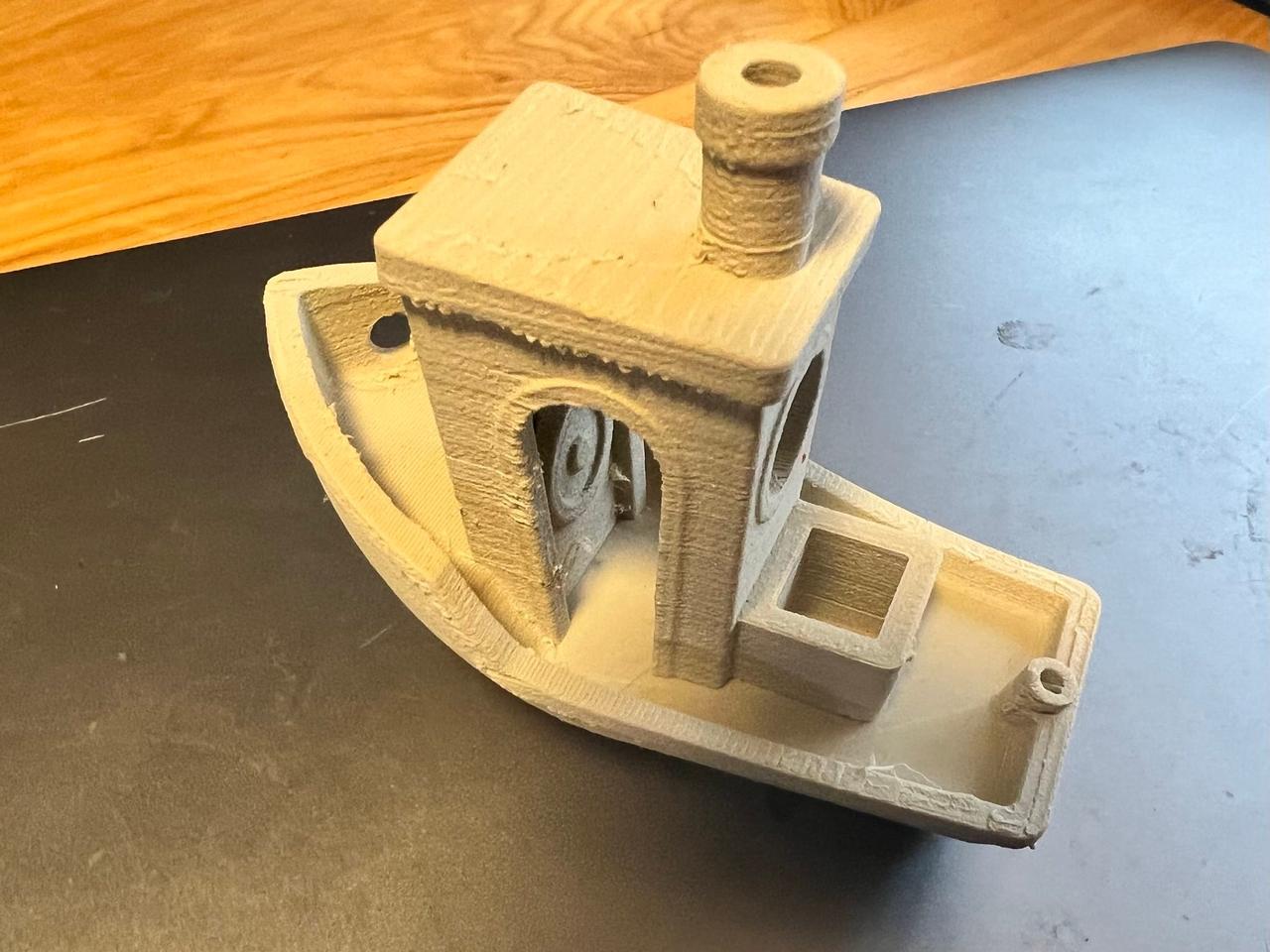

One of the biggest challenges of 3D printing with nylon and glass fiber filament is getting the print settings just right. The material requires specific settings to achieve a successful print, and these settings can vary depending on the specific brand and type of filament being used. If the settings are not correct, the print may not adhere properly to the bed, causing warping or detachment during printing. Additionally, nylon with glass fiber filament is more prone to stringing and oozing during printing, which can leave unsightly and difficult-to-remove strands of filament on the printed object.

One of the biggest challenges of 3D printing with nylon and glass fiber filament is getting the print settings just right. The material requires specific settings to achieve a successful print, and these settings can vary depending on the specific brand and type of filament being used. If the settings are not correct, the print may not adhere properly to the bed, causing warping or detachment during printing. Additionally, nylon with glass fiber filament is more prone to stringing and oozing during printing, which can leave unsightly and difficult-to-remove strands of filament on the printed object.

Another challenge is maintaining a consistent temperature throughout the printing process. Nylon and glass fiber filament require high temperatures to melt and print correctly, but if the temperature is too high or too low, the filament can become brittle and break during printing. Maintaining the right temperature can be difficult, especially for larger or more complex prints, as the filament may cool down or heat up unevenly in different parts of the object.

Post-processing can also be a challenge with nylon and glass fiber filament prints. Because of the material's strength and durability, it can be difficult to sand or smooth the surface of the printed object without damaging it. Additionally, the material is more difficult to paint or coat, which can limit the options for finishing the final product. Also, being chemically resistant to solvents and other chemicals also means it is difficult to vapor smooth objects made with the composites (or even just pure nylon alone).

With all of the background information on nylon with glass fiber out of the way, let's discuss the details of getting functional and great looking printed components.

I found that the Cura settings used for nylon + carbon fiber work very well. The only tweak I made was increasing the temperature of the print bed by 5° and this resulted in better adhesion. The other adjustment to the process that I was making sure the print bed was cleaned each time I printed - soap and hot water - as well as putting on a fresh thin layer of glue stick on the bed. Glue stick seemed to work better than the more expensive Magigoo for nylon. Since I already covered the Cura settings in the carbon fiber post, I won't duplicate them here.